User experience is an important aspect to consider when designing a device. In fact, it can even

determine the success of a product. Designers must therefore ensure that the user interface is functional,

intuitive and easy to use. Especially, it is important to select appropriate components that are responsible for interacting with the device.

In today's article, we will discuss the most common types of components responsible for human-machine interaction, their distinctive features and when to choose each of them.

What components are used to control the device?

Below is a summary of the most common components and technologies responsible for communication between the user and the device.

PCB–mounted tactile and miniature switches

Switches are one of the basic electronic components, used to connect and disconnect an electrical circuit. Their main application is to control the operation of various devices – including switching on and off, entering data, as well as resetting the device.

Micro switches are available both as surface-mount or through-hole components. Some kinds are designed to be placed on the edges or in the board cutouts. We can also choose between

monostable and bistable switches, as well as switches with different electrical and mechanical properties.

Read also:

Electronic component assembly technologies

The simplicity of tactile switches also means their versatility.

Starting from very basic applications, such as switching on a LED or activating a particular function of the device, it is also possible to create more advanced circuits, such as a custom keypad.

Examples of surface-mount tact switches. There is a wide range of buttons and switches available on the market with different sizes, features and purpose

Examples of surface-mount tact switches. There is a wide range of buttons and switches available on the market with different sizes, features and purpose

InterElcom offers a

wide selection of switches – including

miniature tactile switches, rotary switches, limit

switches and

DIP switches. We work with the best manufacturers to ensure that our products always meet your expectations and needs. We encourage you to browse the product catalog, and to ask questions in the

contact form.

Anti-vandal switches

At the other end of the spectrum you will find large, heavy-duty switches, usually designed to be mounted in a panel or enclosure. They are designed for the most demanding applications. They owe their name to increased durability and resistance to damage. Some of them are also

waterproof, or have a built–in backlight. Their large size makes it easier to use them in difficult conditions or when wearing gloves.

Switches of this type are usually found in public use equipment, like elevator panels or intercoms. Their robustness also makes them the preferred solution for industrial applications, for example in

operator panels or control cassettes.

Membrane buttons

Membrane buttons are one of the simplest kinds of monostable switches. They consist of a properly shaped piece of flexible plastic or rubber, whose inner part is covered with a conductive layer. It sits right above the PCB, which has appropriately placed contact pads. When the button is pressed, it deforms and the conductive part comes into contact with the pads below, closing the circuit.

Their main advantage is the possibility of

almost unlimited customization of their shape, size and graphic overlay design. You can make a button of any shape and color, or put a symbol or text on it. Moreover, additional features can be placed on the membrane keyboard alongside the buttons. These may include text descriptions, graphics or even a transparent display window. All of these features give a wide range of possibilities to adapt the design of membrane buttons to specific needs. Their

greater contact resistance, however, renders them incapable of switching high currents.

Membrane switches are found in most modern computer keyboards, TV remote controls and calculators, among other things. They are also used in a variety of industrial applications.

Encoders

Encoders are devices that convert mechanical rotary motion into electrical pulses. They have two signal outputs, which provide information about the direction and speed of rotation of the axis. By counting the pulses on each output, it is possible to determine the exact position of the encoder.

Encoders are primarily used in various fields of automation, in electric drives and moving assemblies where

precise motion control is required. In this article, however, we will focus on encoders designed specially for interaction with the device. More specifically, these are small

incremental encoders, usually designed for

PCB mounting. Their axes are meant to be operated by hand, usually with knobs or dials. Most commercially available components of this type also have a built–in switch, which is activated by pressing the knob. Thanks to this, a single encoder is sufficient to navigate in a simple user interface – turning allows you to select a given item in the menu, pressing – to activate it. Encoders can also replace potentiometers in applications such as volume control.

When choosing an encoder for your application, it is best to start with experienced and proven suppliers of electronic components, of which InterElcom is one. For example, our

EC1103S–D5–F10 encoder is ideal for controlling simple devices and navigating their user interfaces. We present its parameters in the table below:

| Symbol |

EC1103S-D5-F10 |

| Type |

Incremental encoder |

| Installation |

SMD |

| Accuracy |

15 pulses per revolution |

| The length of the pin |

5mm |

| Shank diameter |

6mm |

| Electrical parameters |

5VDC, 1mA |

An example of an encoder application that almost everyone has encountered is the scroll wheel on a computer mouse. They can also be found in various types of audio devices, laboratory equipment, and household appliances. Due to their wide functionality and simplicity of implementation, encoders are also widely used in DIY projects.

Control sticks and joysticks

Stick manipulators allow for an accurate reproduction of human hand movements, which are translated into electrical signals. For this reason, they are used wherever

precise control is essential, such as an excavator arm, a

remote–controlled vehicle or a video tracking system. They are also used as computer peripherals, in the form of video game controllers. However, their use in smaller devices, in particular handheld ones, is limited. This is mainly due to size restrictions and the lack of a stable surface, which is important to ensure an adequate level of precision and comfort of use.

There are two types of joysticks: digital (discrete) and analog.

Digital joysticks are much simpler in operation – they usually have four contact elements that are activated by moving the stick in one of 8 directions.

Analog joysticks, on the other hand, work with a set of

potentiometers (adjustable resistors) – one for each axis. Their resistance changes smoothly as the stick moves – thanks to this, the position of the stick can be accurately determined. Joysticks can also be divided based on the number of axes and the number of stable positions. Some types of sticks also feature additional buttons, which are operated by fingers.

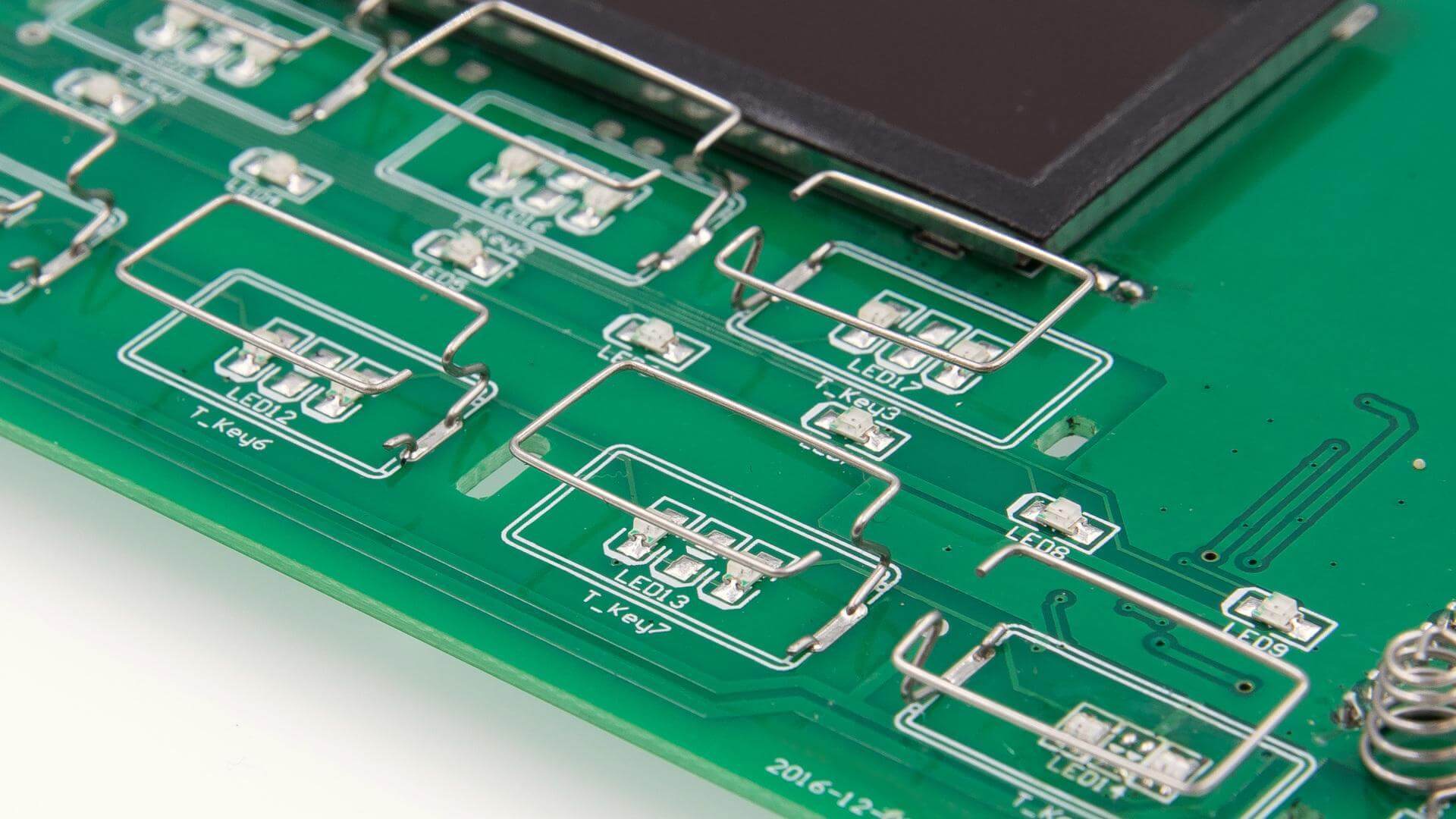

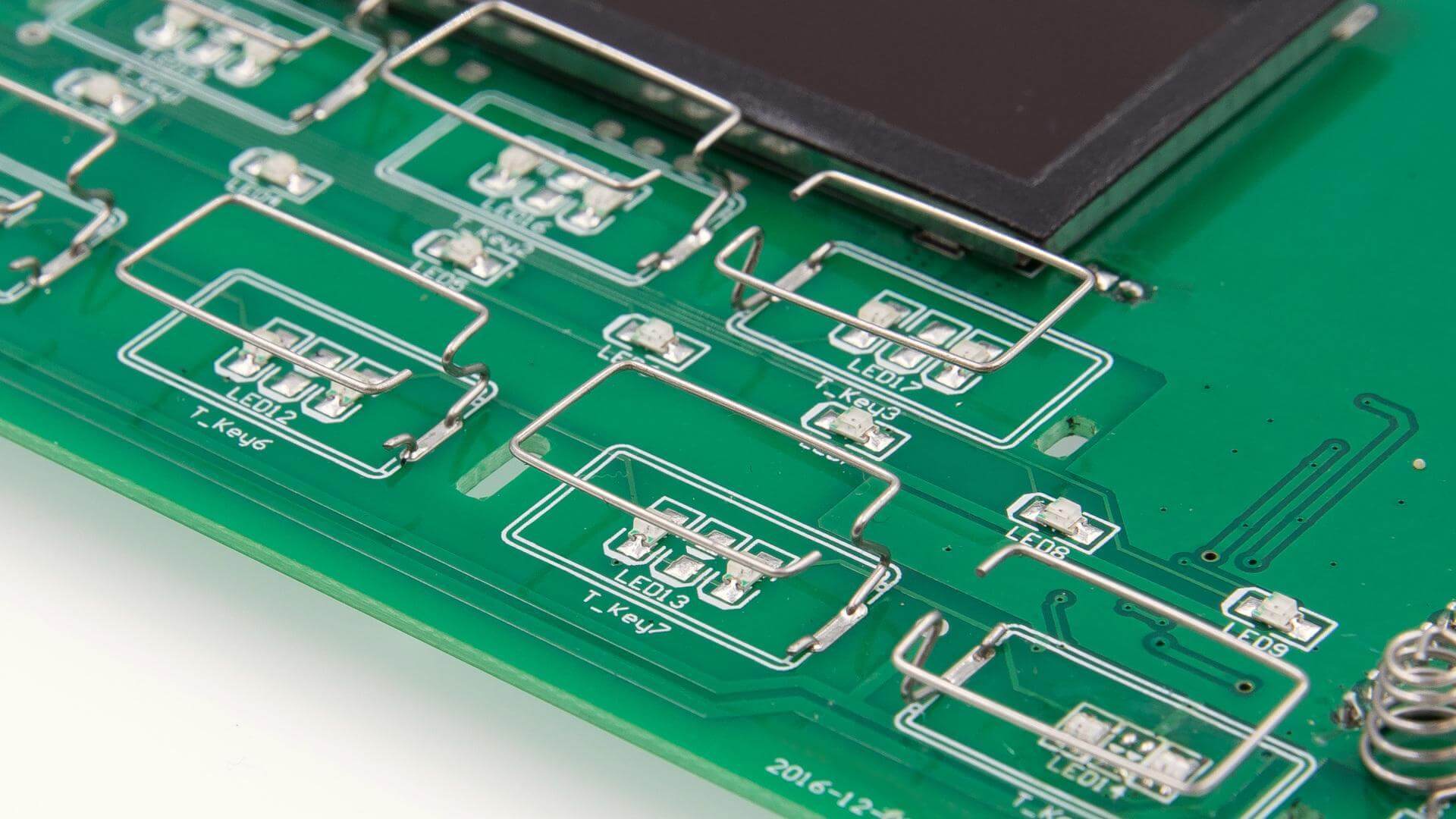

Capacitive switches

Capacitive buttons work on the same principle as

capacitive touch displays. They utilize the natural electrical conductivity of the human body to trigger the switch. Bringing the hand closer or touching the capacitive element causes disturbance in its electric field, which is then detected by a dedicated circuit.

Typically, these types of switches have a form of spring-shaped electrodes, which are pressed against the inner part of the touch panel. There are also solutions in which the function of electrodes is performed by PCB pads or electroconductive layers applied to plastic or glass.

Example of a device with capacitive buttons. The wire loops visible in the picture act as capacitive electrodes.

Example of a device with capacitive buttons. The wire loops visible in the picture act as capacitive electrodes.

The main advantage of capacitive keys is the absence of any moving parts, which translates into

high reliability and long service life. For this reason, they are often used to replace classic mechanical switches in some areas. Perfect examples of this are

door buttons in public transport vehicles, or pedestrian crosswalk buttons. In addition, touch technology has also found its way into various household appliances and consumer electronics, where its share is constantly growing.

However, capacitive touch buttons have certain limitations – first of all, they

cannot register the touch of non–conductive materials. The presence of moisture can interfere with their operation, which excludes them from some applications. Another disadvantage is that the activation of capacitive buttons is not perceptible – it is not accompanied by any sensation or sound, so they are often considered less intuitive to operate. For this reason, additional elements are often used to provide feedback to the user when the button is actuated – these are most commonly light or sound elements,

haptic motors or piezoelectric transducers.

Touch panels

When discussing touch interaction, it is impossible not to mention the rapidly growing popularity of touch displays. They certainly belong to one of the most intuitive methods of operating devices. They are also outstanding in their

flexibility – interactive elements of the graphic interface can be freely and dynamically adjusted depending on given needs. However, the implementation of a touchscreen display can be quite demanding in terms of computing power. Simple devices without a powerful microprocessor may not be able to handle the GUI.

Read also:

Touchscreen displays – types and applications

Still, the use of a display has many other benefits. No additional cutouts in the housing means fewer potential entry points for moisture or dust. This makes it easier to protect the device from the elements, as well as adapting it to operate in more demanding conditions. Touchscreen displays also have a

modern look and provide a high level of aesthetics, which makes them particularly appealing for the end user.

InterElcom offers a wide range of

touchscreen displays for every application – from industrial equipment to mobile phones and smartwatches. We invite you to take a look at

our product portfolio.

Examples of surface-mount tact switches. There is a wide range of buttons and switches available on the market with different sizes, features and purpose

InterElcom offers a wide selection of switches – including miniature tactile switches, rotary switches, limit switches and DIP switches. We work with the best manufacturers to ensure that our products always meet your expectations and needs. We encourage you to browse the product catalog, and to ask questions in the contact form.

Examples of surface-mount tact switches. There is a wide range of buttons and switches available on the market with different sizes, features and purpose

InterElcom offers a wide selection of switches – including miniature tactile switches, rotary switches, limit switches and DIP switches. We work with the best manufacturers to ensure that our products always meet your expectations and needs. We encourage you to browse the product catalog, and to ask questions in the contact form.

Example of a device with capacitive buttons. The wire loops visible in the picture act as capacitive electrodes.

The main advantage of capacitive keys is the absence of any moving parts, which translates into high reliability and long service life. For this reason, they are often used to replace classic mechanical switches in some areas. Perfect examples of this are door buttons in public transport vehicles, or pedestrian crosswalk buttons. In addition, touch technology has also found its way into various household appliances and consumer electronics, where its share is constantly growing.

However, capacitive touch buttons have certain limitations – first of all, they cannot register the touch of non–conductive materials. The presence of moisture can interfere with their operation, which excludes them from some applications. Another disadvantage is that the activation of capacitive buttons is not perceptible – it is not accompanied by any sensation or sound, so they are often considered less intuitive to operate. For this reason, additional elements are often used to provide feedback to the user when the button is actuated – these are most commonly light or sound elements, haptic motors or piezoelectric transducers.

Example of a device with capacitive buttons. The wire loops visible in the picture act as capacitive electrodes.

The main advantage of capacitive keys is the absence of any moving parts, which translates into high reliability and long service life. For this reason, they are often used to replace classic mechanical switches in some areas. Perfect examples of this are door buttons in public transport vehicles, or pedestrian crosswalk buttons. In addition, touch technology has also found its way into various household appliances and consumer electronics, where its share is constantly growing.

However, capacitive touch buttons have certain limitations – first of all, they cannot register the touch of non–conductive materials. The presence of moisture can interfere with their operation, which excludes them from some applications. Another disadvantage is that the activation of capacitive buttons is not perceptible – it is not accompanied by any sensation or sound, so they are often considered less intuitive to operate. For this reason, additional elements are often used to provide feedback to the user when the button is actuated – these are most commonly light or sound elements, haptic motors or piezoelectric transducers.